Replacing and repairing the undercarriage can be one of the highest costs of owning and operating a tracked machine. Unfortunately, undercarriage maintenance is not a task you can put aside for a rainy day since it plays a key role in your machine’s overall performance, no matter if you’re on steel or rubber tracks. Similar to a car in misalignment, worn undercarriages can reduce safety and efficiency and lead to costly downtime.

.png?width=425&height=425&name=rubber%20and%20steel%20tracks%20(1).png)

No matter if you have a rubber or steel tracked machine, proper undercarriage maintenance is essential to preserving component life.

While regular inspections and proper maintenance will help lower your owning and operating costs, it is also important to make sure you have the right undercarriage for your machine and application. Working with the wrong undercarriage system is a common mistake. It can be easy to purchase an undercarriage that is not well-suited for your application, as there are several different undercarriage configurations that meet different application requirements.

When selecting an undercarriage, consider job site conditions. The terrain will dictate the required track and shoe width and number of shoe grousers. You typically want to use the narrowest shoe and track width possible because the unnecessary weight of an oversized track and shoe will increase the rate at which the bushings, sprocket, roller, and idler wear. If you are working on soft, uneven ground or on a slope, a wide track will provide better stability and flotation and do less damage to the ground. Narrow shoes are better for high-impact applications as they are less likely to bend and will put less stress on the track train. Triple grouser shoes should be used in most general construction applications as they offer better maneuverability with lower penetration and resistance.

When setting up your undercarriage system, make sure you have the right track tension. If your tracks are tight, they’ll place unnecessary resistance on the undercarriage components, which can result in early wear. Loose tracks have a higher risk of coming off and increasing your downtime. You’ll find a lot of variances in track tension tolerances, so check your machine’s operation manual for specific track tension information. Big excavators with standard sprocket designs and large steel tracks have different sag rates than rubber-equipped compact track loaders with elevated sprocket designs. When in doubt, consult with your machine sales representative. They can guide you through the selection process and make recommendations based on your needs.

Regular undercarriage inspections can help identify potential problems before they become bigger, costlier problems.

Once you have the correct undercarriage configuration, it’s time to focus on proper maintenance. Although undercarriage management can take some time and effort, the work will pay off as it will help improve performance, extend component life, and maximize your return on investment. Performing regular inspections is one of the best preventive maintenance measures you can take to extend the life of your undercarriage. Depending on your machine’s hours, you should complete an in-depth inspection annually to help you catch potential problems before they become bigger, costlier problems. Before operating the machine, operators should do a walkaround inspection to look for signs of misalignment, leaks, cracks, and significant wear.

Daily cleanings are another easy way to preserve your undercarriage. Dirty undercarriages can lead to jammed moving parts and cause components to snap under protest. If possible, use a power washer to blast built-up debris from the undercarriage. Identify the machine’s grease points and lubricate them daily.

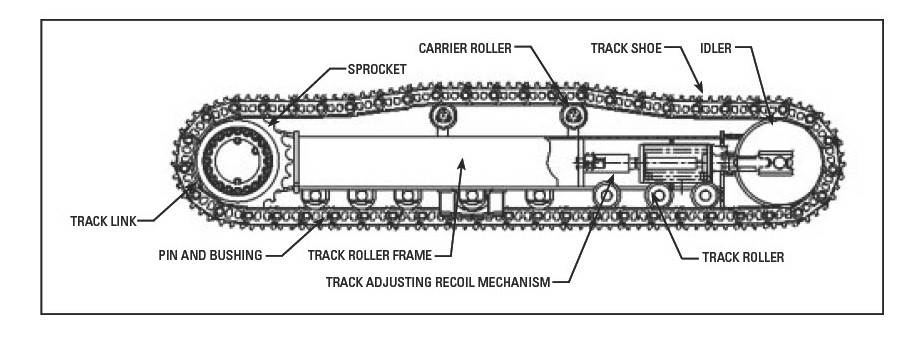

During an inspection, check for wear, cracking, and loose parts in the undercarriage's sprockets, idlers, guide plates, rollers, and links.

.png?width=630&height=540&name=rubber%20and%20steel%20tracks%20(1).png)