Implementing a scheduled oil sampling or S•O•S program can be a valuable tool for guiding your machine maintenance & repair decisions. The sample results can help you identify problems before they become a much bigger, costlier problem by providing insights into the health of your machine. These indicators can be a sign of contamination in your components such as water, antifreeze, fuel, or even dirt ingestion. Other indicators in components like bearings or gear wear, can also be detected through sampling to help prevent a catastrophic failure. Although there are numerous benefits of oil sampling, to maximize your investment made into oil sampling you should be committed to the practice of regularly sampling and acting on the results.

Consistency is key when it comes to oil sampling since abnormal patterns can be warning signs of major component issues. Regularly testing your machine’s oil establishes a basis for normal test results. Sample results that deviate from the established trend may indicate a problem. Three to five oil samples are needed to establish a trend.

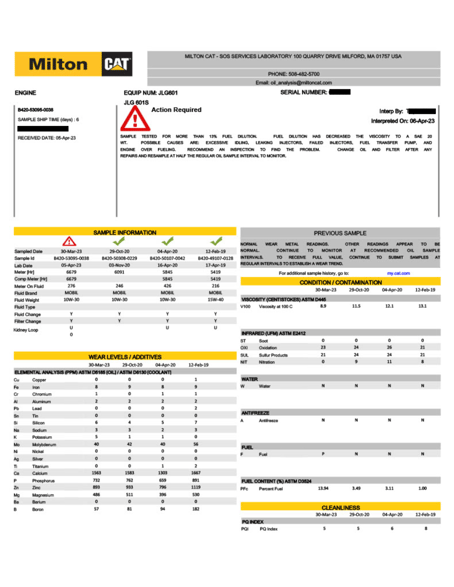

Since S•O•S consists of multiple different tests, interpreting the results can be overwhelming. Using a S•O•S program provider that knows about your equipment, not just the oil, can make interpreting the results easier as you will receive a summary interpreting the results and a recommended course of action. However, you should still review the results for yourself so you can get a better understanding of how your machine is functioning.

Once the oil sample is collected, it is sent to a lab for analysis. The lab looks for indicators of wear, contamination, and other issues that may be affecting the performance of the machine.

Familiarizing yourself with the layout of the S•O•S report can make interpreting the results less daunting. There are six main sections of an S•O•S report including:

- Label Information: Includes the data supplied by you including company name, machine serial number, machine model, hours, and job site. Label information is used to register your sample into a database and allows the S·O·S sample history to be displayed on the report.

- Lab Control Number: A unique number the lab assigns to your sample to help the lab track the sample through all the analyses.

- Overall Evaluation: A color-coded report indicating the urgency of any needed actions. Review the red reports first since these are the most urgent. Then the yellow reports and finally the green reports.

- S•O•S Results: This section indicates the test name and its results. The elemental analysis will list each element individually and display the result.

- Interpretation: Summarizes the findings of the S·O·S results and provides recommendations. Suggested actions may be to resample to verify findings or to monitor wear more closely.

- Explanation of Abbreviations: An explanation of the abbreviations used throughout the report.

As you review your oil sample report, here are some warning signs to look out for.

Coolant: Coolant in the oil may indicate a plugged water pump weep hole which could lead to major engine failure.

Fuel: Your machine’s injector may be bad if fuel is detected in the oil. If not remedied, the fuel quickly breaks down the viscosity of the oil which in turn can lead to component breakdown.

Viscosity: Reported in centistokes (cSt @ 100°C). Measures a lubricant’s resistance to flow. Viscosity changes indicated improper servicing, dilution, contamination, or lubrication breakdown.

Silicon: If silicon is found in your oil, it is a good indication that there may be a pinhole in a filter or a loose or broken filter housing clamp.

Sulfur: Reported in terms of percent allowed. During combustion, fuel sulfur oxidizes and combines with water to form sulfuric acid. Acid corrodes engine parts but is most dangerous to valves and valve guides, piston rings, and liners.

Oil sample report indicating required action. The sample tested for more than 13% fuel dilution possibly indicating excessive idling, leaking injectors, failed fuel transfer pump, or engine over fueling.